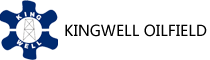

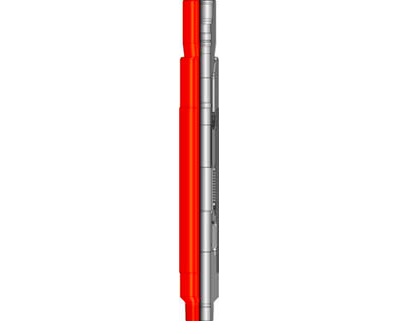

Super Safety Valve

Overall length w/handing sub: 142.65"

Valve section length: 50.90"

Ram lock: 5.0" OD x 18.0" LONG

Valve body OD: 8.0"

Handing subOD: 8.16"

The Super Safety valve (SSV) is a master valve used for testing operations from jack-up or land rigs. The SSV is installed in the test string so that a BOP ram can be closed on the ram lock sub located in the top section of the valve. The annulus is then protected by the BOP rams, and the test string is protected by the safety valve. The Super Safety valve is capable of cutting wireline and 1.5-in. coiled tubing. If equipped with a cutter ball, it is capable of cutting 2-in. OD, .125-in. wall coiled tubing using a nitrogen dome charge or by applying balance line pressure

Features and Benefits

The Super Safety valve is controlled by two hydraulic lines and contains a chemical injection port for injecting chemicals at the valve body further downhole to an injection sub or to actuate a subsurface safety valve. The valve is held open by maintaining hydraulic pressure on the control line. The valve is designed to close by spring force but incorporates a nitrogen dome charge chamber to provide increased closing force and to lessen the time required for closing. This feature gives the valve the ability to cut wireline and coiled tubing without adding balance line pressure.

• Normally closed/fail-safe

• Maintains pump-through capabilities at all times

• Nitrogen dome charge for fast response

• Capable of cutting 1.5-in. coiled tubing, or if equipped with a cutter ball 2-in. OD, .125 in. wall thickness coiled tubing

• Small 8-in. OD fits inside 9 5/8-in casing

Specifications:

1. Halliburton type, all could change with Halliburton parts.

2. All equipments are produced according to API standard NACE MRO175-2002

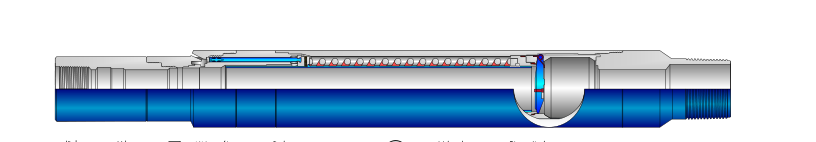

Sub sea Safety Valve

Briefly Introduce

Body 9CR1M0,

Seats: Incolloy 925,

Service H2S/CO2,

OD (Max) 7.69",

ID (min) 4.562",

Test Pressure 7500 #,

Temp. 20-300 F,

standard:Nace MR-01-75/ISO 15156.

Subsea safety valves (SSSV) are safety-critical when a well hassufficient reservoir pressure to flow naturally. Among other things, they areused to secure offshore wells during hurricanes to prevent pollution in theunlikely event the wellhead sustains damage. They are tested regularly and mustbe reliable.

While testing a SSSV in one of its wells in the Campeche Bay, amajor Latin American Operator discovered scale deposits that prevented the SSSVfrom sealing shut. The operator was looking for an alternative mechanicalsolution, since pumping acid into its wells had not been effective. A downholetractor service provider approached the operator and after carefully studyingthe case, presented the wishbone honer brush design run on a well tractor andelectric line to repair the valve in situ and avoid costs associated withmobilizing a rig and removing well components. It was the first time thistechnology was used successfully for this application.